Our Product

Raised Flooring

Raised Flooring For Control Rooms . Different Type Of Panel Finish Hpl Vinyl Or Carpet

Raised floor is an elevated cement floor panel, or chipboard floor panels HPL finish, that can be used as access floor that in all servers and control rooms with power and data cables, beside the advantage of covering it with many colourful

Carpets or vinyl finishes, its a long last flooring type that allow for maintenance and replacement of the tiles it self with damaging any other element’s, the load capacity of this floor has minimal capacity of 800 kg on one sqm till

Concentrated of a uniform load of 1200 kg on one sqm, calcium sulphate panels as also a good choic for the raised floor panels type..

______________________________________________________________________________________

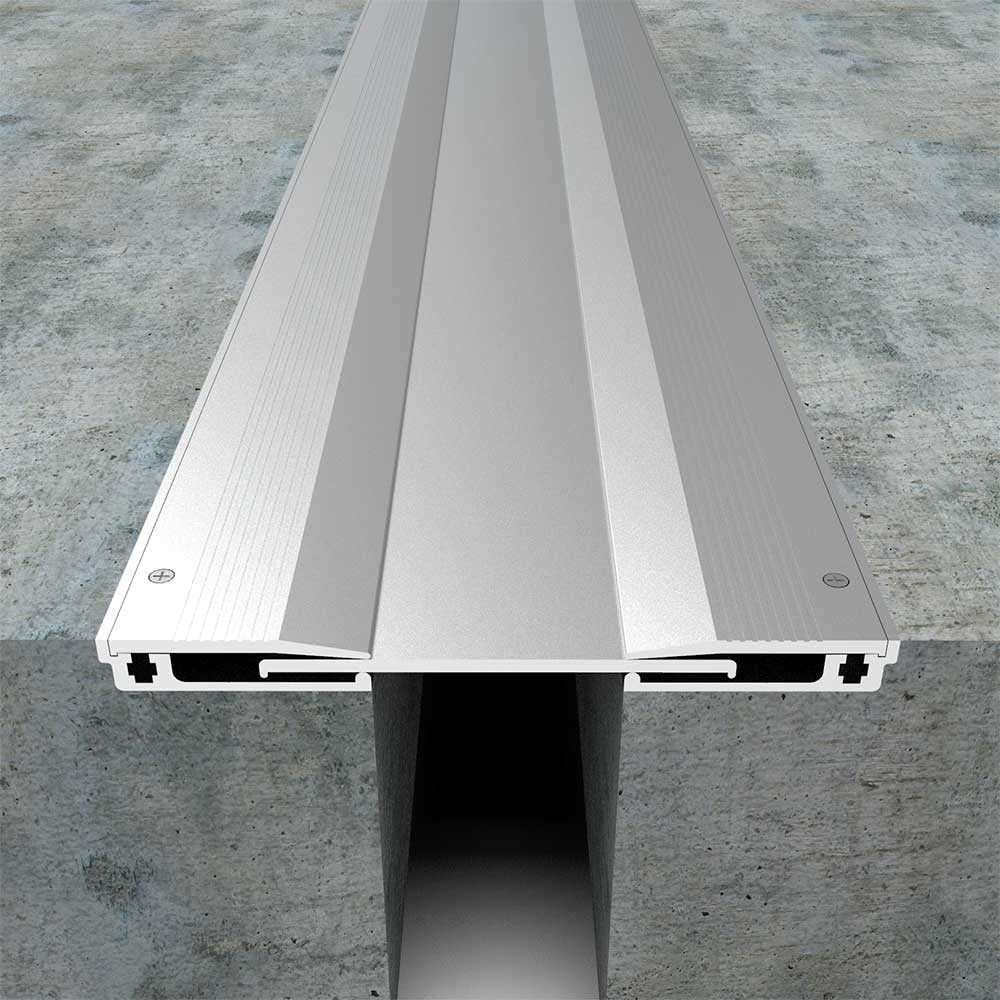

Expansion Joint Cover

We Supply All Kind Of Expansion Joint Covers, Wall, Floor, Parking, Roof, Internal, And External .

Any kind of Expansion Joint need to be covered by Aluminum cover or Aluminum system and could stainless steel as well, so the Expansion Joint cover

Protect the joint itself and make the movement capability is more flexible and intact , floor cover or wall cover or ceiling cover and roof cover could be from the same material and the same finish while parking will be completely different, our Expansion Joint cover could be provided with fireproof or fire barrier and fire stop material along with water barrier and waterproofing which would enhance the mechanism of the joint beside the possibility of the maintenance of the joint itself three years by replacing the Expansion Joint cover or maintain it.

______________________________________________________________________________________

Fire Barrier & Fire Stop Systems - Cermic Fiber Insulations.

We provide a different solutions with a developed technology for the building protection, so our fire stop and fire barrier rope products along with Ceramic high temperature insulation blanket, provide a complete range of fire retardant features for residential and industrial construction types.

Fire stop systems are essential components of building construction aimed at preventing the spread of fire, smoke, and toxic gases through openings in fire-rated walls, floors, and ceilings. These systems are designed to protect the structural integrity of buildings and provide occupants with crucial time to evacuate in the event of a fire.

Here are some key aspects of fire stop systems:

Purpose: Fire stop systems are installed in openings such as electrical, plumbing, or HVAC penetrations, as well as expansion joints and gaps in fire-rated walls and floors. Their primary purpose is to seal these openings and prevent the passage of fire, smoke, and toxic gases between compartments or structural elements.

Fire Resistance Ratings: Fire stop systems have defined fire resistance ratings, which indicate the amount of time they can withstand exposure to fire and maintain their integrity. These ratings are given in terms of hours (e.g., 1 hour, 2 hours) and are determined through rigorous testing in accordance with international standards, such as ASTM E814 or UL 1479.

Components: Fire stop systems typically consist of various components, including fire-resistant sealants, intumescent materials, fire wraps, collars, pillows, and putty. These components are selected based on the nature of the opening and the required fire resistance rating. They work together to create a barrier that can expand, char, or resist the passage of fire and smoke.

______________________________________________________________________________________

Drywall And Partitions Systems .

______________________________________________________________________________________

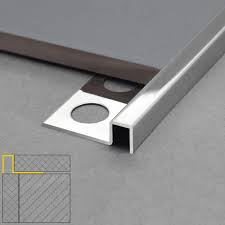

Aluminum Entrance Matt and Floor Matt

______________________________________________________________________________________

Rubber wall guard protection system